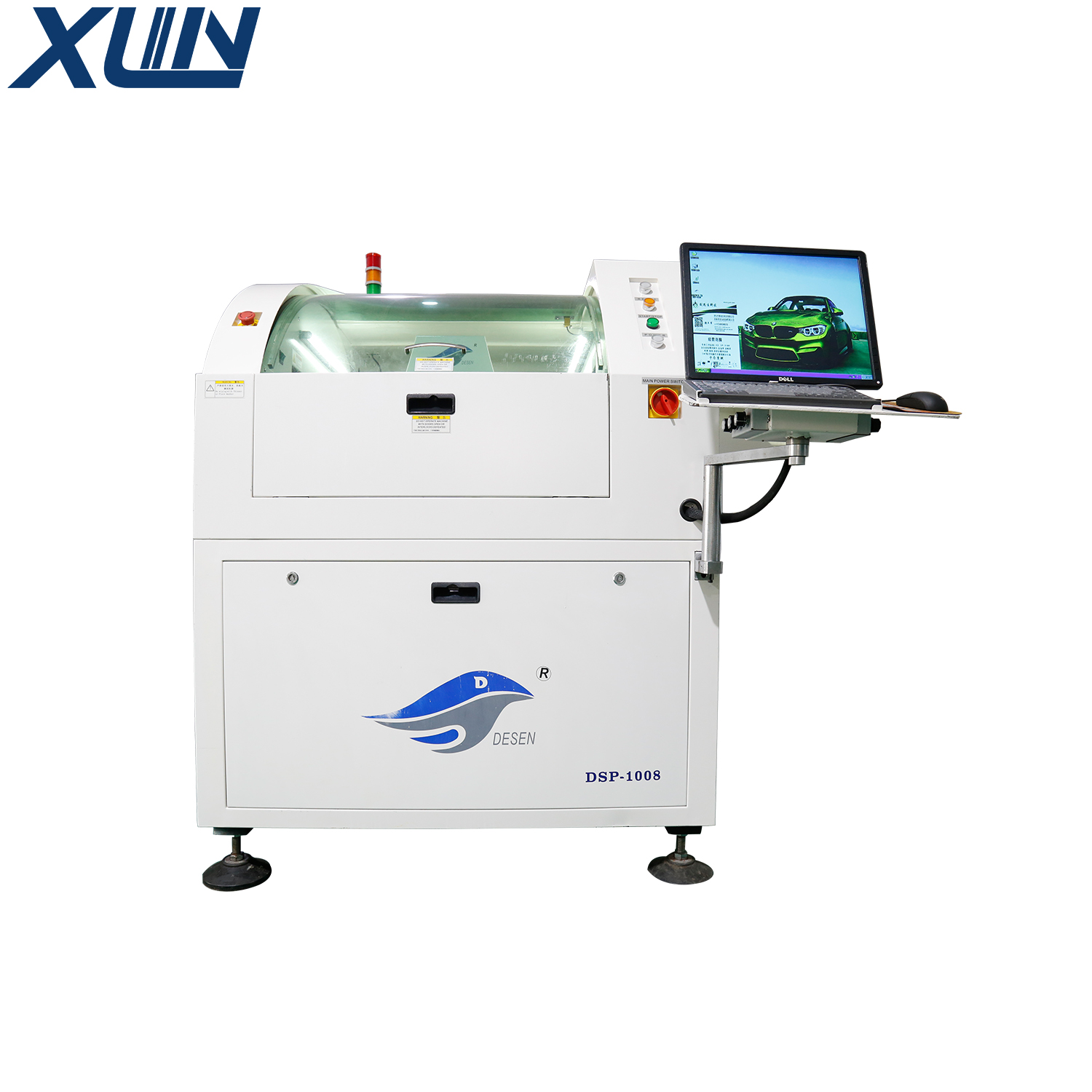

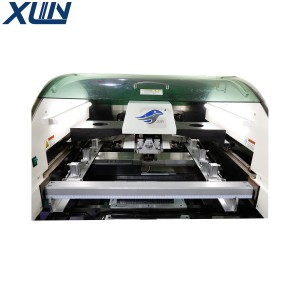

Isantya esiPhezulu esiZizimelayo esiPheleleyo se-PCB SMT Solder Cola Isishicileli se-PCB SMT Stencil Printer

Umatshini wokushicilela we-solder wanamhlanje ngokubanzi uqulunqwe ngokulayishwa kwepleyiti, ukongeza i-solder paste, i-embossing, ukuhanjiswa kwebhodi yesekethe njalo njalo. Umgaqo wayo wokusebenza ngulo: lungisa kuqala ibhodi yesekethe ukuba iprintwe kwitafile yokubeka indawo, kwaye emva koko i-scrapers yasekhohlo nasekunene yomshicileli ivuza i-solder paste okanye iglu ebomvu kwipadi ehambelanayo nge-mesh yentsimbi. I-PCB ene-uniform engekhoyo yoshicilelo igalelo kwi-mounter ngokusebenzisa itafile yothumelo lokunyuka okuzenzekelayo.

Amanyathelo okusebenza kwe-SMT yomshicileli ozenzekelayo:

1. Khangela kwaye uqale izixhobo ngaphambi kokuba usebenze ngokweenkqubo zokusebenza;

2. Beka i-PCB (i-PCB deformation ayikwazi ukuhlangabezana neemfuno zokuvelisa, kwaye ipleyiti exhasayo iya kongezwa) kwisakhelo sokulayisha;

3. Beka isikrini kumatshini wokushicilela ngokwesalathiso esikhonjwe lutolo lwesikrini;

4. Khetha inkqubo yoshicilelo ehambelanayo ngokweemveliso eziveliswayo, ngenisa * * indlela yokulinganisa isikrini, kwaye ulungise imeko yoshicilelo;

5. Uhlengahlengiso lokushicilela: lungisa isantya sokushicilela, uxinzelelo kunye ne-angle ukwenza inani le-solder paste liprintwe kwi-uniform ye-PCB pad;

6. Inqaku lokuqala liya kuqinisekiswa yingcali kunye nokuveliswa kobuninzi kuya kuqhutywa emva kokuba ifanelekile;

7. Zonke iibhodi eziprintiweyo ezingama-30 ziya kuhlolwa ngumhloli kwaye zithunyelwe kwisixhobo sokuxhobisa emva kokuphumelela uhlolo;

8. Emva kokusebenza, susa ibhodi yesikrini kwaye uyicoce, uyivale ngokweenkqubo zokusebenza, kwaye uhlambulule i-worktable.

Iimfuno ze-SMT umshicileli ozenzekelayo:

1. Nxiba iiglavu zerabha okanye iiglavu ezilahlwayo xa usebenzisa i-solder paste. Ukuba i-solder paste ibambelele ngengozi esikhumbeni, yihlambulule ngokukhawuleza ngotywala kunye ne-sanitizer yesandla, uze uyihlambulule ngamanzi amaninzi;

2. I-solder paste eseleyo, iphepha elisetyenzisiweyo lokusula isikrini kunye neeglavu ezilahlayo emva kokusebenza ziya kunyangwa ngokuhambelana nemimiselo efanelekileyo yemimiselo yendalo;

3. Coca izixhobo, izixhobo kunye nezixhobo phambi kokusetyenziswa, ngakumbi nikela ingqalelo ekhethekileyo kwimeko yokhuseleko lokusingqongileyo kwindawo phambi kokuba kusetyenzwe iimveliso ezingenalothe.

Iiparamitha zePCB

Umzekelo DSP-1008

Ubungakanani bebhodi enkulu (X x Y) 400mm×340mm

Ubuncinci bebhodi yebhodi 50mm×50mm

PCB ubukhulu 0.4 - 5mm

Iphepha leWarpage ≤1% Diagonal

Ubunzima bebhodi ephezulu 0-3kg

Isikhewu somda webhodi yi-20mm

Isantya sokutshintshela 1500mm/s(Ubukhulu)

Ukutshintshela ubude ukusuka emhlabeni 900±40mm

Isalathiso sokutshintshela kwi-orbit eKhohlo-Ekunene, Ekunene-Ekhohlo, Ekhohlo-Ekhohlo, Ekunene-Ekunene

Imowudi yokuGqithisela inqanaba elinye lokujikeleza

I-PCB yendlela yokudambisa i-PCB elungisekayo Uxinzelelo lwecala olunoguquguqukayo + Ubukhulu bebhodi yePCB eguquguqukayo + i-Edge lock base clamp (NgoKhetha: 1. I-vacuum yamanqaku amaninzi asezantsi; 2. Isitshixo seEdge kunye ne-substrate clamping)

Indlela yenkxaso yeMagnetic thimble, ibhloko elinganayo ephezulu, njl.njl.

Iiparamitha zokuSebenza

Ukuphindaphinda ukuchaneka kolungelelwaniso lomfanekiso ±10.0μm @6 σ,Cpk ≥ 2.0

Ukuphindaphinda ukuchaneka koshicilelo ±20.0μm @6 σ,Cpk ≥ 2.0

Ixesha lomjikelo<7s(Ngaphandle kokuprinta kunye nokucoca)

Ukutshintshwa kwemveliso<5mins<br /> Iiparamitha zomfanekiso

Indawo yokujonga 8mm x 6mm

Uluhlu lohlengahlengiso lweqonga X: ± 5.0mm, Y: ± 7.0mm, θ: ± 2.0 °

Indawo yebenchmark Uhlobo lwemilo esemgangathweni yebenchmark point(SEMA standard),solder pad/openings

Inkqubo yekhamera Ikhamera ezimeleyo,indlela yokubona phezulu/ezantsi

Iiparamitha zoShicilelo

Intloko yoshicilelo Intloko yoshicilelo edadayo (injini ezimbini ezizimeleyo eziqhagamshelwe ngokuthe ngqo)

Ubungakanani besakhelo setemplate 470mm x 370mm~737 mm x 737 mm

Eyona ndawo yokushicilela (X x Y) 450mm x 350mm

Uhlobo lwe-Squeegee I-Steel scraper / i-Glue scraper (Ingelosi 45 ° / 50 ° / 60 ° ehambelana nenkqubo yokushicilela)

Ubude be-Squeegee 300mm (ukhetho kunye nobude be-200mm-500mm)

Ubude be-Squeegee 65±1mm

Ubungqingqwa be-Squeegee 0.25mm I-Diamond-efana nekhabhoni yokwaleka

Imowudi yoshicilelo Ushicilelo olunye okanye oluphindwe kabini lwe-scraper

Ubude be-Demoulding 0.02 mm - 12 mm

Isantya sokushicilela 0 ~ 200 mm/s

Uxinzelelo lokushicilela 0.5kg - 10Kg

Ukuprinta istroke ±200 mm (Ukusuka embindini)

Iiparamitha zokucoca

Imodi yokucoca 1. Inkqubo yokucoca i-drip; 2. Iindlela ezomileyo, ezimanzi kunye ne-vacuum

Ubude bokucoca kunye nokusula ibhodi 380mm (ukhetho kunye ne-300mm, 450mm, 500mm)

Izixhobo

Iimfuno zamandla 220±10%,60/60HZ-1¢

Iimfuno zomoya ezixinisiweyo 4.5~6Kg/cm2

Ubungakanani bangaphandle 1114mm(L)*1360mm(W)* 1500mm(H)