Abantu abaninzi basenokungayazi indlela yokusebenzisa umatshini wokubeka, bachaze umgaqo womatshini wokubeka, kunye nokusebenza ngokukhuselekileyo. Ishishini le-XLIN liye labandakanyeka ngokunzulu kumashishini omatshini wokubeka iminyaka eyi-15. Namhlanje, ndiza kubelana nawe ngomgaqo wokusebenza kunye nenkqubo yokusebenza ekhuselekileyo yomatshini wokubeka.

Umatshini wokubeka: owaziwa nangokuthi "umatshini wokunyuka" kunye ne "Surface Mount System", kumgca wokuvelisa, ulungelelaniswe emva komatshini wokukhupha okanye umatshini wokuprinta isikrini, kwaye inkqubo yokunyuka kwendawo ifakwe ngokuhambisa intloko yokunyuka. Isixhobo esibeka ngokuchanekileyo amacandelo kwi-PCB pads. Umatshini wokubeka yindibaniselwano yomatshini, umbane, ukukhanya kunye neteknoloji yokulawula ikhompyutha. Ngokufunxa, ukufuduswa, ukubekwa, ukubekwa kunye neminye imisebenzi, amacandelo e-SMC/SMD anokukhawuleza nangokuchanekileyo ancanyathiselwe kwindawo echongiweyo yepad yePCB ngaphandle kokonakalisa amacandelo kunye nebhodi yesekethe eprintiweyo.

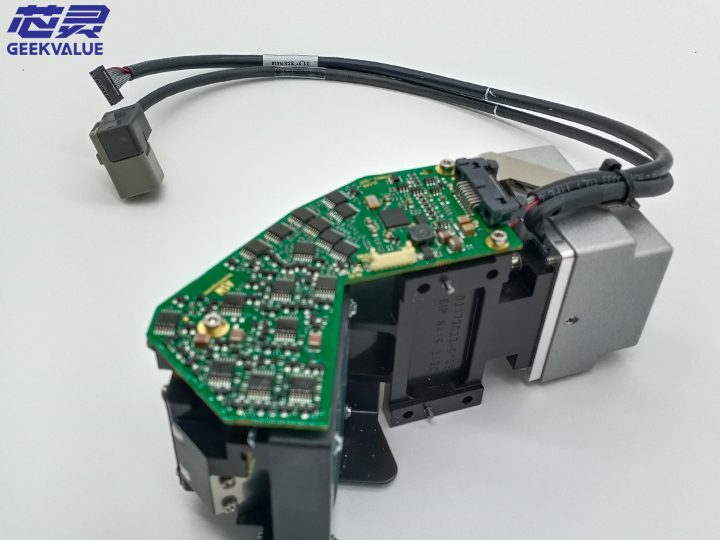

Kukho iindlela ezintathu zokubeka amaziko kumatshini wokubekwa: ukugxininiswa koomatshini, ukugxininiswa kwelaser kunye ne-visual centering. Umatshini wokubeka unesakhelo, i-xy motion mechanism (i-ball screw, i-linear guide, i-drive motor), intloko yokubeka, i-component feeder, i-PCB ephethe indlela, isixhobo sokufumanisa ukulungelelaniswa kwesixhobo, kunye nenkqubo yokulawula ikhompyutha. Ukushukuma kwawo wonke umatshini kuqondwa ngokuyintloko yi-xy movement mechanism, amandla ahanjiswa sisikrufu sebhola, kwaye intshukumo ye-directional iphunyezwa ngomzila we-rolling linear guide. Le fomu yokudlulisa ayinayo kuphela ukuchasana kwentshukumo encinci, isakhiwo esincinci, kodwa kunye nokusebenza kakuhle kokuhanjiswa.

1. Kukho iintlobo ezimbini zoomatshini bokubeka: i-manual kunye ne-automatic ngokupheleleyo.

2. Umgaqo: I-arch-type component feeder kunye ne-substrate (PCB) zilungisiwe, kunye nentloko yokubeka (efakwe kunye nemibhobho yokufunxa emininzi) ihamba emva naphambili phakathi kwe-feeder kunye ne-substrate ukususa amacandelo kwi-feeder. Lungisa indawo kunye nolwalathiso, uze unamathele kwi-substrate.

3. Ngenxa yokuba intloko yesiziba ifakwe kwi-X/Y yokulungelelanisa umqadi oshukumayo wohlobo lwe-arch, ngoko ithiywe.

4. Indlela yokulungelelanisa indawo kunye nolwalathiso lwamacandelo e-arch uhlobo lwe-mounter: 1), ulungelelanise indawo nge-mechanical centering, kwaye ulungelelanise ulwalathiso ngokujikeleza umbhobho wokufunxa. Ukuchaneka ukuba le ndlela inokuyifumana ilinganiselwe, kwaye iimodeli zamva azisasetyenziswa.

5. Ukuqaphela i-Laser, i-X / Y yokulungelelanisa indawo yokulungelelanisa inkqubo, i-suction nozzle rotation adjustment direction, le ndlela inokuqonda ukuchongwa ngexesha lokuhamba, kodwa ayinakusetyenziselwa icandelo lokubonisa igridi yebhola ye-BGA.

6. Ukuqaphela ikhamera, i-X / Y yokulungelelanisa indawo yokulungelelanisa inkqubo, i-suction nozzle rotation adjustment direction, ngokubanzi ikhamera igxininisekile, kwaye intloko yokubeka ibhabha inqumle ikhamera ukuqatshelwa kwe-imaging, ethatha ixesha elide kune-laser recognition, kodwa iyakwazi ukuqaphela. naliphi na icandelo, kwaye kukho kwakhona ukuphunyezwa Inkqubo yokuqaphela ikhamera yokuqatshelwa ngexesha lokuhamba kwendiza ineminye imibingelelo ngokubhekiselele kwisakhiwo soomatshini.

7. Kule fomu, ngenxa yomgama omde wentloko ye-patch ehamba phambili naphambili, isantya sinqunyelwe.

8. Ngokuqhelekileyo, imilomo yokufunxa i-vacuum emininzi isetyenziselwa ukuthabatha izinto ngexesha elinye (ukuya kuthi ga kwishumi) kunye nenkqubo ye-double-beam isetyenziselwa ukunyusa isantya, oko kukuthi, intloko yokubeka phezu komqadi omnye ithatha izinto; ngelixa intloko yokubeka komnye umqadi incamathela Ukubekwa kweCandelo kuphantse kube kabini ngokukhawuleza njengenkqubo yomqadi omnye.

9. Nangona kunjalo, kwizicelo ezisebenzayo, kunzima ukufezekisa imeko yokuthatha izinto ngexesha elifanayo, kwaye iintlobo ezahlukeneyo zamacandelo kufuneka zitshintshwe kunye nemibhobho yokucoca i-vacuum, kwaye kukho ukulibaziseka ekutshintsheni imibhobho yokufunxa.

10. I-feeder yecandelo lohlobo lwe-turret ifakwe kwinqwelo yezinto ezihambayo zokulungelelanisa, i-substrate (PCB) ifakwe kwi-worktable ehamba kwi-X / Y yokulungelelanisa inkqubo, kwaye intloko yokubeka ifakwe kwi-turret. Xa usebenza, izinto Imoto ihambisa icandelo lesondlo kwindawo yokuchola, umbhobho wokufunxa ufunxa kwintloko yesiziba ithatha amacandelo kwindawo yokuchola, kwaye ijikelezisa ukuya kwindawo yokuchola nge-turret (180). izidanga ukusuka kwindawo yokuthatha). Lungisa indawo kunye nolwalathiso lwamacandelo, kwaye ubeke amacandelo kwi-substrate.

11. Indlela yokulungelelanisa indawo yecandelo kunye nolwalathiso: ukuqaphela ikhamera, i-X / Y yokulungelelanisa indawo yokulungelelanisa indawo, i-suction nozzle self-rotation adjustment direction, ikhamera esisigxina, intloko yokubeka indiza phezu kwekhamera ukuqaphela umfanekiso.

Ukongeza, umatshini wokubeka uphawula iindawo ezibalulekileyo ezinje ngeeshafti ezixhomayo, iilensi ezihambayo/ezimileyo, izibambi ze-nozzle kunye ne-feeders. Umbono womatshini ungabala ngokuzenzekelayo ulungelelwaniso lwezi nkqubo zeziko lokumakisha, ukuseka ubudlelwane bokuguqulwa phakathi kwenkqubo yokulungelelanisa umatshini wokubeka kunye nenkqubo yokulungelelanisa ye-PCB kunye namacandelo afakwe, kwaye ubale ulungelelwaniso oluchanekileyo lomatshini wokubeka. Intloko yokubeka ibamba umlomo wokufunxa, kwaye ifunxa amacandelo kwindawo ehambelanayo ngokohlobo lwephakheji, inombolo yecandelo kunye nezinye iiparitha zamacandelo okubekwa kwamanye amazwe; i-lens engatshintshiyo ibona, ibone kwaye ibeke amaziko amacandelo okufunxa ngokwenkqubo yokubonwayo; kwaye idlula kwintloko enyukayo emva kokugqitywa Khupha amacandelo kwi-PCB kwiindawo ezimiswe kwangaphambili. Uluhlu lwezenzo ezifana nokuchongwa kwecandelo, ukulungelelaniswa, ukufumanisa, kunye nofakelo zonke zigqitywe ngokuzenzekelayo yinkqubo yokulawula emva kokuba ikhompyutha yoshishino ifumene idatha efanelekileyo ngokwemiyalelo ehambelanayo.

Umatshini wokubeka isixhobo esisetyenziselwa ukubekwa kwamacandelo aphezulu kunye nokuchaneka okuphezulu, kwaye sesona sixhobo sibaluleke kakhulu kwaye sinzima kuyo yonke imveliso ye-SMT. I-Mounter sisixhobo sokufakela i-chip esisetyenziswa kwimveliso ye-SMT. Umatshini wokubeka ukubeka ngokuchanekileyo umatshini wokubeka kwindawo ehambelanayo, kwaye emva koko unamathele ngeglue ebomvu efakwe ngaphambili kunye ne-solder paste, uze ulungise umatshini wokubeka kwi-PCB nge-oven yokubuyisela.

Ukusebenza ngokukhuselekileyo komatshini wokubeka kufuneka kulandele le migaqo ilandelayo yokhuseleko kunye neenkqubo:

1. Umbane kufuneka ucinywe xa uhlola umatshini, ukutshintshwa kweengxenye okanye ukulungiswa kunye nokulungiswa kwangaphakathi (ukugcinwa komatshini kufuneka kuqhutywe ngeqhosha likaxakeka okanye ukucinywa kombane.

2. Xa "ukufunda ukulungelelanisa" kunye nokulungelelanisa umatshini, qiniseka ukuba i-YPU (iyunithi yeprogram) isesandleni sakho ukuze ukwazi ukumisa umatshini nangaliphi na ixesha.

3. Qinisekisa ukuba isixhobo sokhuseleko “se-interlock” sihlala sisebenza ukuvalwa nangaliphi na ixesha, kwaye ukuhlolwa kokhuseleko lomatshini akunakutsitywa okanye kuncitshiswe, kungenjalo kulula ukubangela iingozi zokhuseleko lomntu okanye zomatshini.

4. Ngexesha lokuvelisa, umqhubi omnye kuphela uvumelekile ukuba asebenzise umatshini omnye.

5. Ngethuba lokusebenza, qiniseka ukuba zonke iindawo zomzimba, njengezandla kunye nentloko, ziphuma kwindawo ehambayo yomatshini.

6. Umatshini kufuneka usekelwe ngokufanelekileyo (usekelwe ngokwenene, ungaxhunywanga kwintambo engathathi hlangothi).

7. Musa ukusebenzisa umatshini kwigesi okanye kwindawo emdaka kakhulu.

Ixesha lokuposa: Dec-17-2022